?

Plastic hot melt riveting technology is used to connect parts made of different materials, especially to achieve mutual connection between thermosetting plastics and hot-melt plastic parts, or to connect plastic parts with metals. This technology utilizes local protrusions (hot melt columns) reserved on molded parts, with corresponding holes on the parts that need to be assembled. The hot melt columns pass through the holes and are reshaped by heating, thereby securing another part. According to different heating methods, hot melt riveting can be divided into two types: hot air hot melt and pulse hot melt.

The plastic hot melt riveting technology utilizes the reserved local protrusions (hot melt columns) on the molded parts, and through heating, the hot melt columns are reshaped to achieve the connection of different material parts. Its core application scenarios include:

The interconnection between thermosetting plastics and hot-melt plastic components;

Mechanical fastening of plastic parts and metal materials.

?

Process classification and heating methods

Hot air fusion:

Heat the hot melt columns, ribs, and other structures to the softening temperature using a hot air blower, and then press them into shape using a cold welding head and cool them to solidify.

Advantage: It can be operated in a single-sided space and has high adaptability to assembly environments.

?

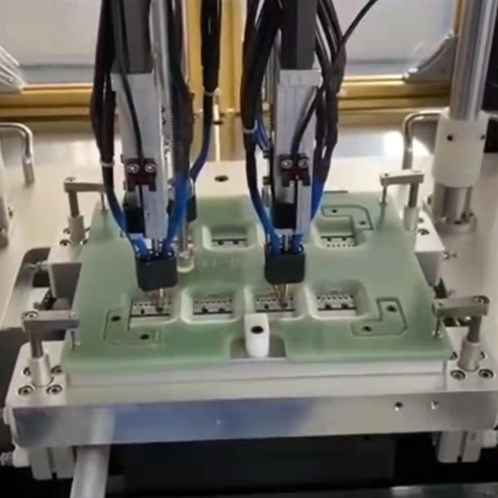

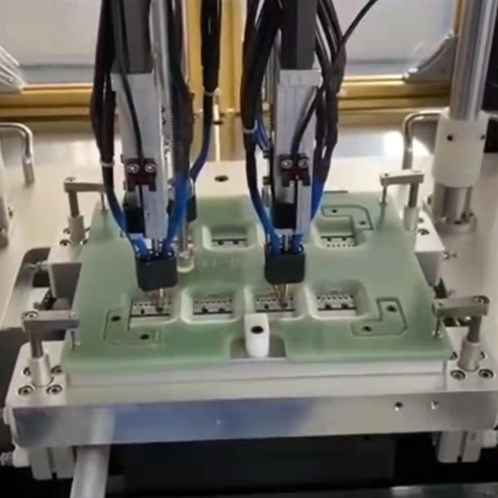

Pulse hot melt:

By using a transformer to generate low voltage and high current, the welding head quickly heats up and softens the hot melt column. After pressure molding, it is accelerated and cooled by cold air.

Advantages: High heating efficiency, suitable for high-precision assembly scenarios.

?

Key structures and equipment

Hot melt column design: including solid columns, countersunk columns, hollow columns, etc., which need to match the aperture of the target part (usually 0.5-1.0mm larger than the hot melt column aperture);

Equipment configuration: The hot riveting machine needs to integrate a temperature control module (such as a PLC system) and a pressure regulating device to ensure the stability of the hot melt forming process.

?

Application scenarios and technological advantages

Cross material connection: suitable for reliable fixation of plastic and metal components in automobiles and electronic devices;

Process flexibility: Diversified structural designs such as countersunk riveting and flanging riveting can be achieved by adjusting the shape of the welding head.